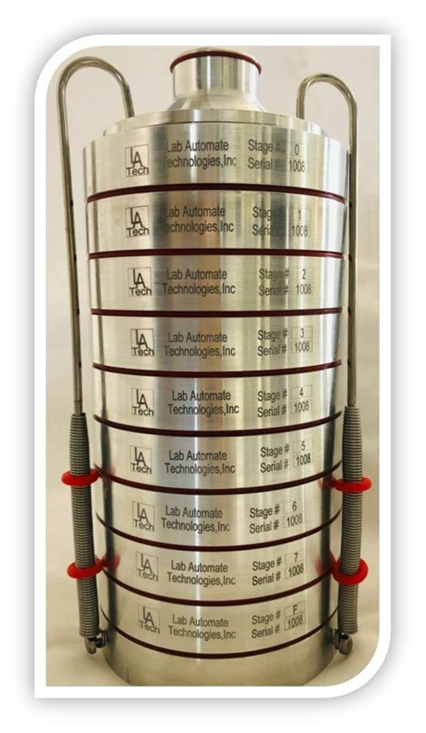

Eight Stage Non-Viable Cascade Impactor

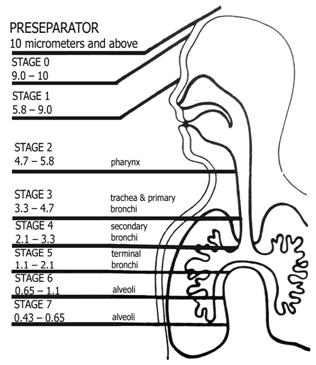

| ECDs (µm)* @28.3 L/min |

Full ACI |

Size Bands (µm) |

| 9.00 | Stage 0 | 9.00—10.0 |

| 5.80 | Stage 1 | 5.80 – 9.0 |

| 4.70 | Stage 2 | 4.70– 5.8 |

| 3.30 | Stage 3 | 3.30 – 4.7 |

| 2.10 | Stage 4 | 2.10 – 3.3 |

| 1.10 | Stage 5 | 1.10 – 2.1 |

| 0.65 | Stage 6 | 0.65 – 1.1 |

| 0.40 | Stage 7 | 0.43 – 0.65 |

| Filter | < 0.40 | |

| ECD = Effective cutoff diameter

IP = Induction Port |

||

Andersen Cascade Impactor Mark II Dimensions as per USP 601 (The Filter Stage is Not Specified)

| Stage # | # Jet Holes | Jet Hole Dia

(mm) |

Tolerance

(mm) |

| 0 | 96 | 2.55 | ±0.0255 |

| 1 | 96 | 1.89 | ±0.0255 |

| 2 | 400 | 0.914 | ±0.0127 |

| 3 | 400 | 0.711 | ±0.0127 |

| 4 | 400 | 0.533 | ±0.0127 |

| 5 | 400 | 0.343 | ±0.0127 |

| 6 | 400 | 0.254 | ±0.0127 |

| 7 | 201 | 0.254 | ±0.0127 |

| F | 340 | 2.794 | ±0.0127 |

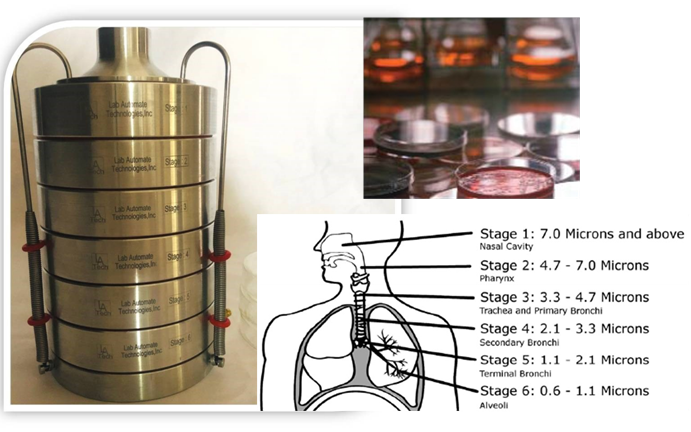

SIX STAGE VIABLE CASCADE

| Stag e # | # Jet Holes | Jet Hole Dia

(mm) |

D50 | Particle Size Range in mi-

crons |

| 1 | 400 | 1.18 | 5.8 | 7 &

above |

| 2 | 400 | 0.91 | 4.7 | 4.7 – 7.0 |

| 3 | 400 | 0.71 | 3.3 | 3.3 – 4.7 |

| 4 | 400 | 0.53 | 2.1 | 2.1 – 3.3 |

| 5 | 400 | 0.34 | 1.1 | 1.1 – 2.1 |

| 6 | 400 | 0.25 | 0.7 | 0.65 –

1.1 |

Biological air sampler, designed to capture viable particles and fractionate sample onto glass or plastic agar plates. Made to the specification of the Andersen design of sampler . Included are a set of Petri Dishes to give you a running start.

SIX STAGE VIABLE CASCADE

The Lab Automate Six Stage Viable Cascade Impactor is a bioaerosol and microbial particle sizing sampler designed to measure the concentration and particle size distribution of aerobic bacteria and fungi in intramural or ambient air for sampling at 28.3 lpm. It is designed & built to the original An-dersen Cascade Impactor (ACI) specification, which is known as the world’s reference bioaersol sam-pler. It is precision-machined out of high-quality aluminum. Each sampling stage has 400 precision machined jet orifices with diameters ranging from 1.81mm on the first stage to 0.25mm on the sixth stage. All collected particles, regardless of size, shape or density are aerodynamically sized.

This impactor works on the principle of inertial separation. When air is drawn through the sam-pler it cascades through the different stages, and the corresponding particulates impact on the agar on the stage and the smaller particulates continue to travel through the stages until they are en-trapped on the corresponding plate or the petri dish containing agar. These viable bacterial particu-lates are then incubated and then counted and identified. They can then be recorded and related to where they may be deposited on the human lung. It allows for size separation from >9μm to <0.3μm.

The Six Stage Viable Impactor comprises of an aluminum inlet cone, six jet stages, silicone seals, six glass petri dishes and a base plate that is held together by three spring action retainer clamps and sealed with high quality silicone o-rings. The spring action retainer clamps allow for easy disassem-bly and cleaning.

APPLICATIONS INCLUDE

-

- Face Mask Qualifications

- Indoor air quality studies

- Pharmaceutical production

- Animal care laboratories

- Wastewater treatment plants

- Cosmetic manufacturing

-

- Filter & clean room efficiency studies

- Brewery fermentation

- Food processing area

- Hospital environments

- Grain processing and transportation

- Agricultural emissions